In the introduction to their findings, the authors have clearly said that the primary use for this tool will be cutting of deep sea cables.

New Delhi: Chinese scientists have developed a 5 kg cutting-edge electric cutting device specifically designed to sever deep-sea cables, a critical advancement in underwater technology with significant strategic implications for its neighbouring countries.

The device was developed by the state China Ship Scientific Research Center (CSSRC) and one of its key laboratories on deep-sea manned vehicles.

It was introduced in a peer-reviewed paper, accessed by this newspaper, published in the Chinese-language journal “Mechanical Engineer” on 24 February.

The paper titled, “Design of an electric cutting device for deep-sea cables” has six authors who are associated with the China Ship Scientific Research Center, a key state laboratory of deep-sea manned vehicles, situated at Wuxi, Jiangsu.

Interestingly, the paper was not available in the online version of the journal, while the rest of the papers published were present.

The Sunday Guardian’s email to the CSSRC elicited no response on this.

In the introduction to their findings, the authors have clearly said that the primary use for this tool will be cutting of deep sea cables.

“In order to cater to the demands

The Sunday Guardian in March 2023 (Concerns arise over safety of India’s undersea data cables) had written about the dangers that damages to these cables would cause. However, until now, no policy has been announced by the government to tackle this strategic challenge unlike in other countries.

In January last year, Prime Minister Narendra Modi had inaugurated the Rs 1,072 crore Kochi-Lakshadweep islands submarine optical fibre connection (KLI-SOFC), which would bring internet to the island city.

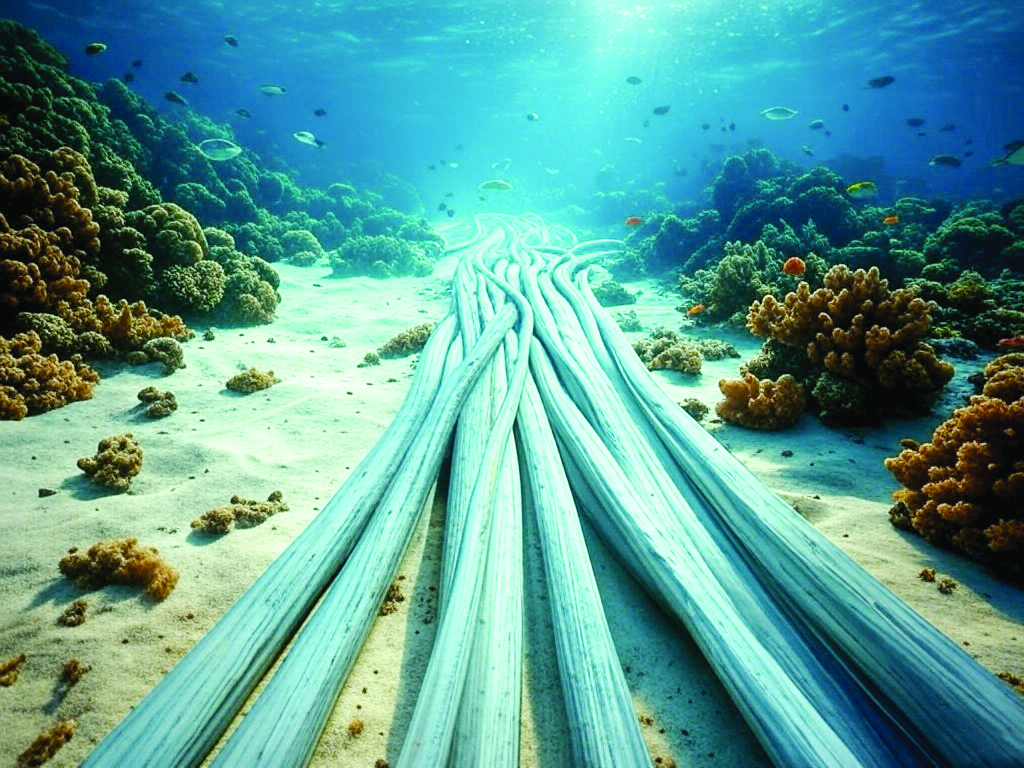

In India, these under-sea cables, which are a part of a global network of cables that carry data, “land” at multiple places—Mumbai, Thiruvananthapuram, Tuticorin, Chennai and Kochi. Apart from these cities, another international landing station is coming up at Mundra, Gujarat, while there are two domestic landing stations at Chennai that connect Andaman and Nicobar Islands, and one at Kochi, which connects the 11 islands of Lakshadweep.

Earlier last week, the chairman of the Telecom Regulatory Authority of India (TRAI), Anil Lahoti had stated that India’s existing submarine cable infrastructure falls short of its digital ambitions and the country “has to do much more” to strengthen its subsea cable network. According to him, India hosts only one per cent of the world’s undersea cable landing stations, in contrast to smaller countries such as Singapore which has 26 subsea cables landed across three landing sites.

Just days before the Chinese made their invention public, US tech giant Meta announced plans to build the world’s longest underwater cable project, which aims to connect the US, India, South Africa, Brazil and other regions. The project named “Waterworth” involved a 50,000 km (31,000-mile) subsea cable, which is longer than the Earth’s circumference and would be the longest to date to use a 24 fibre-pair system, giving it a higher capacity.

The paper written by the Chinese researchers further goes on to say that this tool will be an important part of the “Chinese dream”.

“As the demand for resources in countries around the world continues to increase, mineral resources such as oil, coal, and natural gas on land have become increasingly scarce, while the ocean covers about 70.8% of the earth’s surface, which contains extremely rich mineral resources, chemical resources, and marine power resources. This has prompted countries to turn their resource development goals to the ocean. The 21st century is the century of the ocean. Improving the ability to develop marine resources, developing the marine economy, and building a strong marine nation are an important part of realizing the ‘Chinese Dream’. Deep-sea equipment plays a pivotal role in the development of marine resources. In recent years, in order to explore and develop marine resources, my country’s deep-sea equipment has made great progress and designed various underwater equipment, including cable remote-controlled underwater vehicles (ROVs), cable-free autonomous navigation underwater vehicles (AUVs), underwater gliders, unmanned submersibles, manned submersibles, etc., and various operating tools have also emerged. Among them, the ‘Jiaolong’, ‘Deep Sea Warrior’ and ‘Struggler’ manned submersibles are important representatives of domestic advanced deep-sea equipment and technology.”

“Deep-sea cables are mainly used for power and telecommunication transmission. They are mainly divided into three categories: communication cables, power cables and optoelectronic composite cables. They are mainly composed of a protective layer, a shielding layer and a conductor layer. Communication cables are mainly used for communication services and contain communication optical fibres. Compared with land-based communication cables, the protective layer is armored with steel wire to prevent accidental disconnection during deployment and fishing boat operations. Power cables are mainly used for underwater transmission of high-power electrical energy to provide power for underwater equipment. Compared with land-based cables, the insulation and tensile strength of the protective layer are greatly improved. Optoelectronic composite cables can achieve efficient communication between optical carriers and power equipment. They are increasingly widely used in practice and have high requirements for signal shielding,” the authors stated.

The said device, as per the findings analysed by The Sunday Guardian, is specifically designed to address the challenges of cutting through deep-sea cables, which are often constructed with multiple protective layers such as steel wires, PVC, rubber, and PE to save them from damage, given the fact that these cables, which include communication, power, and optoelectronic composite cables, are essential for power and telecommunication transmission at great depths.

So far, their complex and durable construction made it extremely difficult to cut them with traditional cutting methods, especially those which are at deep depths, as most internet cables are.

Why is the Chinese device a major breakthrough?

The new device developed by the Chinese scientists overcomes these challenges.

One of the key innovations of this design is its ability to operate at depths of up to 4,000 metres, where the pressure can reach up to 40 megapascals (MPa). This makes it suitable for approximately 90% of submarine internet cables, which are typically found at depths ranging from 1,500 metres to 4,000 metres.

The device has been specifically engineered to withstand the harsh deep-sea environment, which presents extreme pressure, temperature variations, and the constant threat of corrosion.

Traditional underwater cutting tools struggle to function properly at such depths due to their vulnerability to pressure-induced leaks, mechanical failures, and the need for bulky external components.

To address these challenges, the Chinese scientists designed a pressure-compensated motor that does not rely on external oil tanks, a common feature in traditional deep-sea cutting systems.

Instead, the motor’s oil compensation system was integrated directly into the motor structure, which significantly reduces its size and weight. This integration has also minimized the risk of leaks and other points of failure that could occur in external oil tanks or hoses.

With a weight of just 5.14 kilograms underwater, the device is lightweight enough to be used with smaller, more cost-effective remotely operated vehicles (ROVs), a significant advantage over traditional systems that require larger ROVs with higher payload capacities.

It is pertinent to mention that China’s deep-sea robot research began in the early 1990s. China has successfully developed “CR-01”, “CR-02” and “Qianlong” series of autonomous underwater robots; “Haidou” series autonomous remote control underwater robot; “Hailong”, “Haima”, “Starfish” remote controlled underwater robots and towed underwater robots.

Its most recent additions have been the manned submersible “Jiaolong”, “Deep Sea Warrior” and “Struggler”, with a working depth of 4,500 metres to 11,000 metres and in which this cable cutting device is likely to be fitted.

The said device’s motor is designed to be oil-filled, which serves multiple purposes. The oil prevents seawater ingress, lubricates the motor, and compensates for the expansion and contraction of materials due to temperature changes and pressure variations at depth.

The motor housing is constructed from titanium or high-strength stainless steel to resist corrosion, and it is sealed with hydrogenated nitrile rubber (HNBR) or fluorocarbon materials, which are known for their ability to withstand the extreme pressures of the deep ocean. The motor uses synthetic dielectric fluid, which is stable and resistant to compressibility, making it ideal for the pressures encountered at depths of up to 4,000 metres.

A major feature of this cutting device is its ability to cut through armoured cables with diameters up to 60 mm. The cutting mechanism is powered by a high-torque brushless DC motor that delivers 6 N·m of torque, ensuring the device can efficiently sever even the most durable cables.

The blade used in the device is made from tungsten carbide or diamond-coated steel, materials that are hard enough to cut through the tough protective layers of deep-sea cables. During testing, the device successfully cut through a 60 mm insulated cable, achieving a 100% success rate in cable severance, a critical performance metric for any deep-sea cable maintenance tool.

The testing of the device was conducted in a water tank simulating deep-sea conditions. The results showed that the cutting device maintained stable speed and torque while cutting, demonstrating its reliability and effectiveness in real-world applications.